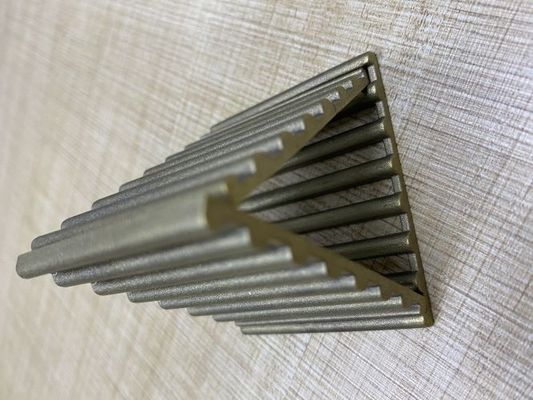

Copper H59 Investment Casting Components 8407 80K Lost Wax Casting

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Copper H59 | Process | HPDC |

|---|---|---|---|

| Mold Steel | 8407 , SKD61 | Mold Temperature | 1100 Degree |

| Mold | 1*2 | Mold Life | 80K |

| Tolerance | +/-0.01 Mm | Test | Three-dimensional Measuring Instrument |

| High Light | 8407 80K Lost Wax Casting,H59 Investment Casting Components,80K Lost Wax Casting |

||

Copper Casting Part Investment Components Lost Wax Casting For Industrial Parts

Industry overview

|

Copper die casting

|

Copper die casting is a high temperature die casting method in which liquid copper or copper alloy is filled into the cavity of a die casting mold at a high speed under high pressure, and the copper or copper alloy solidifies under pressure to form a casting. Advantages: High casting precision, can produce parts with complex structure, high production efficiency and suitable for mass production. Disadvantages: Because of high temperature (900-1100 degrees), high density, so on the equipment, mold, material melting process requirements. |

| Advantage | Copper alloys, which conduct electricity well and have diamagnetic properties, are commonly used in the manufacture of instruments that do not allow interference by magnetic fields. |

| Advantage | Copper alloy has small coefficient of friction, small coefficient of linear expansion, and high wear resistance, fatigue limit and thermal conductivity. |

| Advantage | Copper alloy has high density and high melting point. Widely used in automobile and motorcycle, transportation, electrical instrumentation, communication and telecommunications, medical and health, mechanical equipment, monitoring, sports equipment, handicrafts, toys, furniture, bathroom, lighting, clothing, shoes, hats, accessories daily necessities and other industries. |

| Copper performance | High hardness, corrosion resistance, commonly used in the casting metal mechanical properties, wear resistance, strength close to steel |

|

Description

|

CUSTOM MADE PRECISION CASTING PARTS

OEM and Customized service

|

|

Material

|

Custom Drawings OEM

|

|

standard

|

ISO ,DIN, AISI, ASTM, BS, JIS, etc.

|

|

Size

|

available in all sizes or as customer's drawings

|

|

Certification

|

ISO9001 2008

|

|

Application

|

Industrial parts,Machinery parts,construction parts,valve parts,train,craft,hydraulic pressure,

agriculturalmachinery,Marine hardware,Auto parts,electric power fittings,food machinery, harness fittings,tools, mining machinery parts |

|

Weight range

|

0.01kg-2000kg

|

|

Machining precision

|

±0.01mm

|

|

Surface treatment

|

Heat Treatment, Polishing, Plating, Machining, Anodizing, shot, sand blasting, zinc plated,

oxide, galvanized etc. |

|

Process

|

lost wax casting process, sand casting process. silicasol casting process

|

|

Production Application

|

Metal parts, Mechanical parts, Marine Hardware, Electric power fitting, Construction parts,Pipe Fitting, Hardware, Auto parts,

Valve parts, Industrial parts, Agricultural machinery, Hinges, etc |

|

CNC and MC Machining

|

Three coordinate measurement machine for testing.

|

|

Service

|

To chart to sample production OEM / ODM

|

|

MOQ

|

Small order is accepted

|

|

Remark

|

Making service as per your requirement or drawings

|

Multiple Production Processes

![]()

Product

![]()

![]()

![]()

FAQ

1. How can I get the quotation?

Please send us the drawing, quantity, weight and material of the product.

2. What kind of file can you read?

PDF, IGS, DWG, STEP,etc...

3. What is your way of packing?

Normally we pack goods according to customers' requirement.

For reference: wrapping paper, carton box, wooden case, pallet.

4. When can I get the samples and your main order time?

For samples: 25-35 days after start to make mold.

For order:30 days, the accurate time depends on product.

5. What's your payment term?

1)Tooling cost 50% deposit and 50% after T1 samples approved.

2) Parts cost Net30

3) Payment Method: Wire