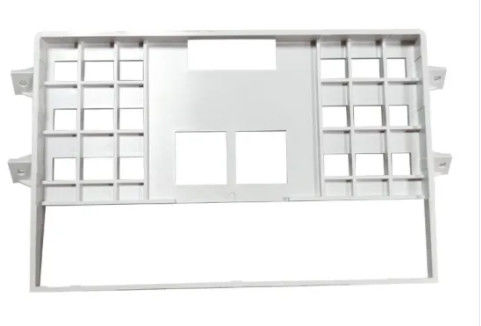

Keyboard ABS Plastic Injection Parts SPI Pin Point Gate Injection Molding

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | ABS, PC | Shaping Mode | Injection Mould |

|---|---|---|---|

| Cavity | Single-Process Mode | Surface Treatment | SPI |

| Runner | Cold Runner | Certification | IATF16949 |

| Application | Electronic | Transport Package | Carton With Pallet |

| Highlight | Keyboard Plastic Injection Parts,SPI Plastic Injection Parts,ABS Pin Point Gate Injection Molding |

||

Tablet Computer ABS Plastic Injection Parts For Wireless Electronic Keyboard Housing

Mold Description

| Mold Standard | DME or HASCO |

| Mold Base | LKM,DME,HASCO,FUTABA |

| Cavity /Core steel | H13,S-7,S136,SS420,NAK80,P20 and other material as requirement |

| Hot Runner | Yudo |

| Cavity | Multi or single cavity |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Hydraulic cylinder | PARKER, TAIYO, STAUBU, JUFAN |

| Mold components | DME, Progressive, PCS, Punch, Royal, etc |

| Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| Surface finish | SPI standard, VDI EDM, Texture, etc |

| Texture | Mold-tech, Yick Sang, Ni Hong ,Tanazawa etc |

| Plastic Material | PP, PC, ABS, PE, HDPE, PET, POM, PMMA, PA(GF), PBT(GF), PVC, PPS,etc |

| Product weight | 5.0g~15kgs |

| Mould Life | 0.3 Million Shots- 1Million shots |

| Delivery Time | 4Weeks T1 samples , exact time depends on Mould Complexity |

| Packaging | Free-Fumigation Three-Plywood case for moulds, cartons for parts |

| Design software | CAD,UG, Pro E, Solidworks |

| Value-added service | Dust-free Spraying, Silk-screen Printing, Ultrasonic Welding, Thermal Bonding, Assembling, Prototype |

| Service area | Transparent, Over mold, double color, air assistant forming, deep barrel, Design R&D, Assembly |

| Our Capability | Auto, Aerospace, Household, Electrical, Industrial, Medial, Toys, Office, Cosmetic, Outdoor, OA Equipment etc |

Services

1. Project Evaluation

2. Product Design

3. Electronic Design and Engineering

4. Mechanical Design and Engineering

5. Prototype Design and Engineering

6. Design for Manufacturing

7. Manufacturing Coordination

8. Mould design

9. Manufacturing

10. Second processing

11. Assembly and etc.

12. One-stop services for plastic parts.

Products Range

Automotive Parts, Industrial Parts, Communication Parts, Household Appliances Parts, Electronics Parts, Cosmetics Parts, Computer Peripherals Parts, Medical Parts, Precision Parts, Equipment Parts...

Mold Type

In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould

Advantages

1. Competitive Price

2. Quick Delivery time (2-4 weeks)

3. ISO Certificated with the srtictest quality control system

4. Many Years OEM Mould-making and Plastic processing experience

5. Advanced equipment and Skilled workers

Research >>> Electronic Design >>> Indusfrial And Mechanical Design >>> Moulds Tooling >>> Moulding >>> Secondary Process >>> Assembly

CNC Workshop

![]()

![]()

FAQ

1. Can you give me help if my products are very urgent?

Yes, we will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

2. I want to keep our design in secret, can we sign NDA?

Sure, we will not display any customers' design or show to other people, we can sign NDA.

3. Can we know the production process without visiting the factory?

We will offer a detailed production schedule and send pictures and videos which show the machining progress.